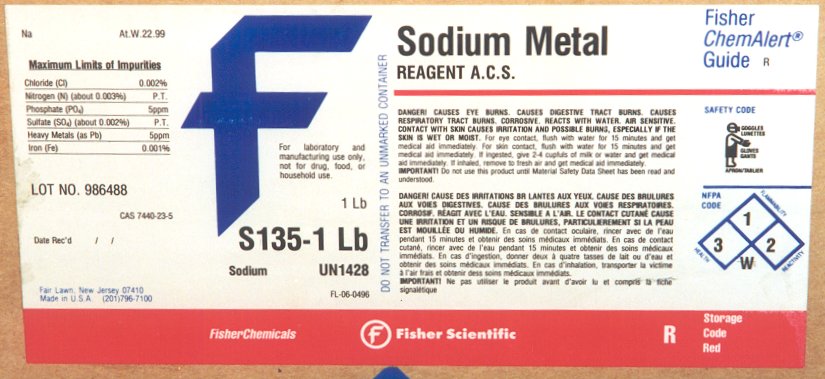

Warning label on sodium package

WARNING

The sodium burn method is so dangerous that the Essene does not even like doing it for base metals (Gold, Iridium, etc.) because of the danger. The black sand they use for the M3 burns (using sodium) is a hundred times less reactive than using gold metal. During our 2 years of perfecting the Essene's gold sodium burn method, we have had many near misses (accidents) and one major explosion where one of our party got boiling NaOH blown into his face during the wet down process. His skin began melting from his face and he looked like a monster. Fortunately he was wearing protective goggles and his eyes were spared. immediately upon the explosion occurring, we drowned his head and face in gallons of distilled water and got him in the shower immediately. He remained there for an hour and then we applied many, many pieces of fresh cut aloe to his face and performed Reiki as well. His mouth had internal burns and his tongue was melting.

This person was into his 3rd bottle of M3 and that along with the other things, allowed him to heal within one month. Now there is not a single sign that the accident occurred.

This procedure makes m-state gold starting with pure gold and sodium. One ounce of gold produces approximately a one-year supply for one person.

OVERVIEW: There are eight main stages in this process:

STAGE 1 - PREPARING THE GOLD: Flatten the gold (about the thickness of aluminum foil) and cut it into small pieces (about 1 hour).STAGE 2 - PREPARING THE SODIUM: Cut a one pound block of sodium metal into 8 strips (each strip is an eighth of a pound) (about 20 to 30 minutes).

STAGE 3 - THE BURN: Apply a high flame to a sealed pan (use clamps to secure the lid to the pan) containing the gold and sodium (15-20 minutes).

STAGE 4 - WETTING THE UN-REACTED SODIUM: Mist the pan's contents with distilled water to react all the sodium. Use extreme caution during this process (1 to 2 hours).

STAGE 5 - BOILING THE SLUDGE IN LYE WATER AND FILTERING THE SOLUTION: Boil the pan's contents in lye water 2 cups of lye to 2 gallons of water. When it cools--either by itself or by adding one gallon of cooling water (always use bottled distilled water)--allow the sediment (fine black looking sand) to settle.

STAGE 6 - REMOVING SULFUR WITH ZINC: Remove any sulfur with zinc (about 5 minutes plus a few days reaction time).

STAGE 7 - FILTER THE SOLUTION: Filter the solution through a grade 111 filter (we use a vacuum flask).

STAGE 8 - TITRATE WITH HCl TO PRECIPITATE M-STATE GOLD: Add HCl to the STAGE 7 filtered solution to bring the pH down to 8.5, resulting in m-state gold precipitate (1 to 2 hours).

Much of this process will be done outdoors. Do

the process on a fair-weather day when rain is not predicted. You do not

want any rain water getting into the pan with sodium in it because sodium

reacts violently with water.

EQUIPMENT

MATERIALS

Equipment:

2. Grab the gold piece with tongs and run the gold several times through the roller until it is thin enough to cut with scissors. We have measured the gold to be 1 thousandth of an inch thick. A normal sheet of paper is 5 thousandths.

3. Cut the gold foil into confetti-size pieces about

3/8" square. Store them in a labeled jar.

Equipment:

Warning label on sodium package

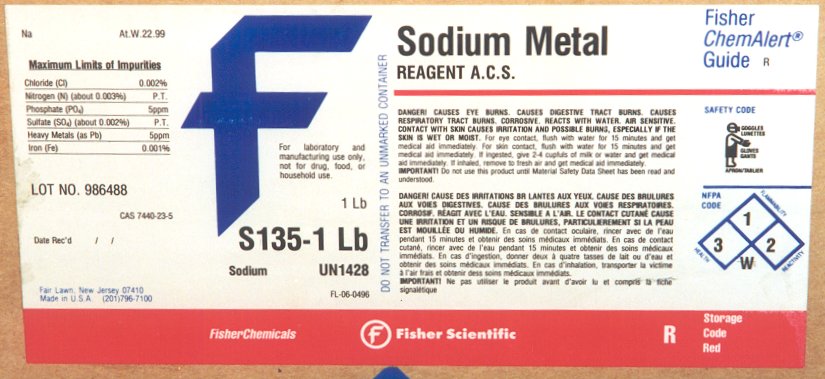

2. Open the sodium container. The sodium is a white, soapy block about 3" X 3" X 4". Place the sodium block on a Teflon cutting board.

3. Using a ruler and a blade, mark the block of sodium with shallow slices every 1/2" or so to mark the block in eight divisions. Later, using those marks, you will cut the block into eight equal pieces.

[illustration - line drawing]

4. Coat the blade with extra virgin olive oil so it will slide through the sodium easier.

5. Cut through the sodium block at each slice mark by pressing down on the ends of the blade with both gloved hands, . This divides the block into eight equal pieces (each piece is about 2 ounces).

Sodium cut into 1/8 inch slice

6. Put seven of the pieces into a glass quart jar. Place a doubled up piece of saran wrap over the jar and place a rubber band around the jar rim to hold the wrap. This allows the sodium to react with the air and moisture in the jar (may out gas a little bit) yet prevents more moisture from getting back in. Remember, sodium metal was once used as a desiccant in electrical telephone switch cabinets and so taking moisture out of a sealed environment is what it does best. After a day or so, the sodium will once again be a nice white color and stable as long as you keep it far away from water. Use common sense here folks.

7. The rubber gloves will get damp because the sodium on the gloves will draw moisture out of the air. Work quickly, but safely. The more moisture on the gloves, the faster the sodium will react.

8. Cut the sodium (2 ounce piece) into smaller squares about 1/8 inch thick and lay the sodium slices in the bottom of the 1-quart sauce pan. They will look like slices of chiclets gum, but don't try chewing them! Cover the bottom of the pan with the sodium slices as best you can. There may be gaps in the mosaic, but that's okay. Try to get as much of the bottom covered as you can . Remember, the thinner you slice the sodium, the more area you can cover. Trial and error is the best teacher here.

Sodium layered in bottom of stainless pan

9. Put the gold "confetti" uniformly on top of the sodium slices.

10. Put on the sauce pan lid and clamp it with six C-clamps spaced evenly around the perimeter. The gaps between the clamps will be sufficient to allow pressure relief during the burn. Be careful to keep the pot level as you transfer it to the burner in order to keep the gold on top of the sodium.

Stainless steel pan with clamped lid

Titanium pot with clamped lid

11. Outdoors, hose down the cutting board, gloves

and knife to remove sodium from them.

Equipment:

Cooker with clamped pan--ready to go

The sodium will react with the gold according to this equation:

3 Na + Au = AuNA3

2. NOTE: Some stainless-steel pans contain an aluminum layer on the bottom, or an aluminum/steel sandwich. The aluminum will melt and drip down. This is not a problem, but don't have any flammable material, like dry grass, under the pan or anything you don't want to get burned by the melting aluminum. A concrete block or patio would be ideal.

Another burn on a patio

3. During the burn, you may see some slight smoke initially as the sodium burns. If you see more smoke later, that's the m-state gold burning off. Stop immediately if that happens.

4. Otherwise, stop the burn 15-20 minutes after you started. (This time will vary depending on the temperature of your heat source.) The flame should engulf the entire bottom of the pan causing it to become a very hot cherry red color. The properly distributed heat allows the sodium to uniformly melt and then does the same for the gold, leaving no "cold" spots.

5. While still wearing safety protection create a lye solution in a well-ventilated area. You can do this as the pan cools on the cooker.l

CAUTION: Lye is very caustic. Do not spill it or splash it. Do not inhale the fumes.

Put 4 cups of sodium hydroxide (lye) into 2 gallons of distilled water in a 12-quart stainless steel pot. Stir well. The solution will get hot.

6. Carefully bring the open pot of lye solution outside.

Do not spill or splash it. Of course you should have the stainless steel

lid on it. You should drill the aluminum rivets out of the handles and

the lid and replace them with stainless steel bolts. The boiling lye solution

will corrode the aluminum rivets right off the pot. Replace the rivets

before boiling to avoid the handles breaking off and spilling the caustic

solution.

STAGE 4: WETTING THE UN-REACTED SODIUM

Equipment:

1. Wearing safety glasses and other protective

clothing, undo the C-clamps on the sauce pan. Remove the lid. Some smoke

will come out.

2. In the pan you will see "the skin of the rhino." It's a gray material with many fissures or wrinkles, and perhaps some gray-green areas. This material is the gold reacted with the sodium, plus some un-reacted sodium. You will react the un-reacted sodium by misting it with distilled water.

Sodium/gold before wetting

3. Spray one puff of water into the pan from about 18 to 24 inches away. As the sodium reacts with the water, there will be bubbles, a little smoke, sputtering sounds, and perhaps some small flames.

CAUTION: Don't inhale the smoke. Step away if there's a big flare-up.

This is the reaction taking place: Na + H2O = NaOH + H

[photo of flames]

4. Spray the material in the pan periodically, letting the reaction die down each time.

CAUTION: Do not spray a lot of water at once onto the sodium in the pan. The sodium and water could react violently, blowing m-state out of the pan. GO SLOWLY.

CAUTION: Don't stir the sludge or bang on the pan, you might open a big pocket of sodium and get a dangerous reaction (read explosion). As the cool down progresses, you will see crusty bubbles form, like those on a pizza. There is unreacted sodium underneath it. When the surface cracks, excess water will seep through and a flare up will occur. The flare up can be minor or like a fireworks display. What controls the flare up is the amount of excess water that has puddled during the cool down. COOL DOWN SLOWLY (at least 2 hours)

Be aware of sodium on the lid of the pan. This is reactive as well. After the pan has been completely cooled down, carefully and slowly spray down the lid into the pan to collect any gold that may have condensed on the lid.

5. Eventually you will see a gray material with black wet bubbles. Any red or orange spots might be due to bismuth in the Canadian maple leaf gold coin, if you started with one.

6. Keep adding water a spray at a time. Let each spray react and die down. Over time the material in the pan will be mostly black with gray areas of un-reacted sodium. Spray those Grey spots. GO SLOWLY.

7. Gradually all the material turns black and bubbly like hot tar. The bubbles are hydrogen from the sodium/water reaction. There may be hidden layers of sodium underneath, accessed by water through a crack in the sludge, causing a flare-up. When most of the sodium/water reaction is done, spray a water stream (instead of a mist) on the material. The stream breaks through the crust and gets at the sodium beneath.

8. When the sludge is completely covered by water, and you can swirl the sludge around and get no further reaction, it's done. It takes us about 2 hours to complete the reaction.

Sodium/gold after wetting

STAGE 5: BOILING THE SLUDGE IN LYE WATER

Equipment:

2. Pour the gold-sodium black sludge from the pan into the lye water. Spray the sludge with water, and scrape the sludge out of the pan into the lye water to remove as much sludge as possible from the pan. Use the plastic spatula or stir rod to scrape the sludge. Wash the sides of the pan as well. Any yellow coloration on the pan bottom is gold you lost. It's plated on the pan bottom.

3. When you have removed as much sludge as possible from the pan, set the pan aside. You now have a 12-quart pot with some black sludge covered by lye water.

4. Put the pot of sludge and lye water on the cooker with the fire turned off.

5. Spray the inside surface of the lye pot with water to get all the material in solution. You should stir the solution well with the spatula.

6. Cover the pot with a lid. You do not need to clamp it.

7. CAUTION: Wear safety glasses and clothing. Light the cooker and set it to full blast. Let the water come to a steady boil for 15 minutes while stirring. Of course you can bring the flame down a bit if the boiling is too rapid, a good rapid boil is nice.

8. Place the lye pot on the burner of a char-broil grille, or use the cooker on low heat. Let the pot simmer for 2-3/4 hours. While this is happening, you can set up the equipment described in Stage 7.

9. At the end of 3 hours, add 1 gallon of distilled water to the pot to cool it.

10. Bring the pot indoors. CAUTION:

Do not spill the caustic lye solution.

STAGE 6: REMOVING SULFUR WITH ZINC

Equipment:

2. After the STAGE 5 boil, pour the filtered solution into one gallon plastic jugs (milk jugs). Fill them up about 3/4 full.

3. Add 1/4 teaspoon of zinc shavings (10 mesh) into each jug, cap it and shake well. Lift the cap slightly then to allow for gas escape and place somewhere safe.

4. Each day, shake the jug once or twice to mix up

the solution (with the cap tightly in place) and then uncap slightly and

set back in place for the day. We do our burn and boil on Saturday morning

and let the solution zinc until the next Saturday when we filter out the

zinc and then titrate. You only have to add the 1/4 teaspoon of zinc once,

not everyday. The zinc will turn into a dark black powder which settles

on the bottom of the jugs. The zinc pulls out the sulfur as zinc sulfate

(This process takes about 5 minutes plus a few days reaction time).

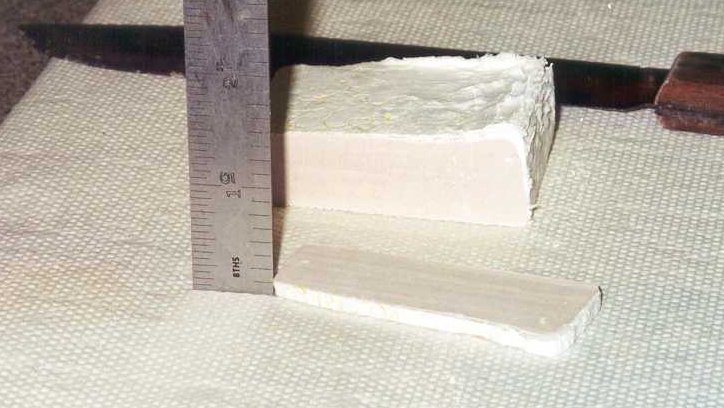

Equipment:

2. Wearing gloves, safety apron and safety glasses, ladle out the liquid part of the solution into quart jars. CAUTION: Lye makes your fingers slippery - you lose grip on jars. Hold jars underneath.

3. Turn on a fan and vent.

4. Put the Buchner funnel into a stopper in a vacuum flask. Connect the vacuum flask to another flask acting as a trap. Connect the output of the trap to a hand pump. Put a filter paper in the Buchner funnel and wet the filter with distilled water so the filter won't float.

Vacuum-flask equipment

An alternative vacuum pump is to connect the vacuum flask to the top inlet of a 5-gallon container of water with a bottom spout that can be opened to create suction.

5. Pour the lye solution from the jar into the filter and pump out the vacuum flask. Black particulate will appear in the filter. Filtered solution will collect in the vacuum flask. When the filter appears to be full, throw it out, put in another, and wet it down. Change the filter every gallon or so.

6. Continue this process, filling jars with filtered

solution. Once the water in the lye pot is mostly gone, you can add more

distilled water and lye to the remaining sludge, re-boil it and filter

it to get more usable m-state material.

STAGE 8: TITRATE WITH HCl TO PRECIPITATE M-STATE GOLD

Equipment:

2. Put one 500 ml jar or beaker on the magnetic stirrer and turn it on. Pour in some filtered solution.

Gallon jug on stirrer with probe stand in background

3. Put the probes in the solution on the stirrer.

4. The starting pH will be approximately 12 due to the lye. Start titrating the acid into the solution in the beaker, checking the pH as you go. CAUTION: Do not breathe the acid fumes.

5. The pH will drop very slowly. Precipitate should begin appearing around 11.5 pH. When the pH reaches 8.5, the precipitate will be a thick white color. That's the m-state gold. Stop adding HCl when you reach pH 8.5.

6. Pour the solution and precipitate into a gallon jug.

M-state precipitate in gallon jugs

7. Repeat steps 2-6 until all the filtered solution has been processed.

8. Wash the precipitate three times with distilled water. If you want to ship the material, do not wash it. Leave it in a salty solution to protect it from X-rays and magnetic fields. It will still need to be washed three times before consumption.

9. Store the m-state gold in a wet precipitate form in well-sealed jugs or jars. Keep the material out of light and away from magnetic fields.

10. The remaining sludge can be re-boiled in lye water, filtered, and titrated to yield more m-state gold precipitate.

11. Do not ingest more than 1 teaspoon per day of the m-state gold precipitate, maybe eventually dropping to 1 teaspoon per week after a year or so.

# # #

Q. Would it be possible for someone to lesson most of the dangers involved by using PPE (personal protective equipment) rubber gear with full face, head and hand protection?

A. When you are trying to use Au metal, protective gear is essential during the wet down phase. I recommend a face shield, wrap around glasses minimum. When doing the M3 with fine sand, there is very little sodium reaction to contend with. I still recommend glasses at all times. There will probably be little droplets coming from the pan which will get on your clothing, so wear something that you can stand losing to tiny holes... As for hand protection, good idea too. make sure it's thick rubber like for dish washing and not surgical gloves which may melt to your hand...

Q. Would cutting the amount of sodium down to 1/10 lb. with 1 cup of sand lesson danger? What would be an appropriate size pan to use with this amount of sand (12 quart?)? Also, is it important to keep a generous amount of sand surrounding the sodium?

A. We are considering exactly that, cutting down to about 1/10 pound of sodium. We are going to cut what we feel is a good thickness and line the pan. We will weigh the pan before and after and give you the weight of sodium metal we use on the next burn. We use a 1 quart saucepan (stainless steel). When you get the bottom covered with the sodium (sliced about 1/8 inch thick), just cover it with the 1 cup of sand. BE SURE TO PLACE THE SAND ON THE RANGE FOR A FEW MINUTES TO MAKE SURE IT'S DRY - PUTTING MOIST SAND ON THE SODIUM WILL MAKE YOUR FACE UNBEARABLE. It's not too important if the sand fills in the cracks, as the sodium will be very molten before the sand does anything. The sodium will digest the sand. I thought I posted a photo of the pan on the cooker... I will try again in a minute...

Q. Can acceptable results be obtained by using less heat than 600-800 degrees C for cooking?

A. We don't know, we never tested the temperature inside the pan, or around it. I guess as long as the stainless steel pan gets RED HOT in just a few seconds, you have enough heat... Remember, there is only sodium and sand in the pan, to it's temperature is limited to the boiling temperature of the materials...

Q. Are there extra steps or tricks of the trade in making M-3 that you would care to give us some information on?

A. Sure. When you have finished wetting down the sand, it will be caked hard like peanut brittle on the bottom of the pan. Don't use too much water in wetting down, because what you should do (our experience) is to use a screwdriver or similar instrument to break up the hardened sand into little chunks about 1/2 square if you can... If you use too much water, you will get splashed with lots of lye (result of mixing Na and H2O). The reason we do this is because you are now going to add the hard sand, lye, and water (in a 12 quart pan) and if you have chunks, you will have more surface area to leach the M-State off of. The Essene pours the water and lye into the same vessel he does the burn in and therefore, I believe is only getting the top surface area leaching M-3... We have had very good yields with our modifications... granted, it adds an extra hazard (splashing lye) to the process, but we really have very little sand to waste... We were using 2 cups of sand, but we always had about 1 cup of powdered sand on top of the hard stuff which demonstrated it was not engulfed by molten sodium and therefore wasted... This is why we now will use 1 cup in our next burn... Another thing is, you can boil the sand 3 times with water and lye and get more material. We got one gallon of M-3 from the initial burn/boil, and another gallon total from the subsequent 2 boils... I suppose you could go through all the trouble of grinding down the dried material into fine sand and then reburning it, but we are grateful for the yields we are getting...

Q. Tell us more about why you add the zinc.

A. When we first began the Au/sodium burn method, we were only getting a caramel colored (sometimes real dirty looking gray) precipitate and only 50 ml or so at that. I remember the first time we even got that, we were in seventh heaven. Someone we consulted about the color said it was a normal thing and that the color could be improved by adding more water to the solution before titrating it. We tried that, but only got less yucky stuff...

After thinking that this process may not be worth the trouble for the yield achieved, I gave a call to the Essene and explained the entire process from start to finish. He pointed out a few (many) foolish things we were doing... As it turns out, there was sulfur getting into our process somehow. We suspected it was the water, and went to Sears and bought a distiller. We were double distilling. We would buy distilled water and run it in the distiller. Still, on the next burn, we got the same results.

We noticed that as we began the titrating, our solution was turning a very deep yellow and was not yielding any precipitate... A call to the Essene again resulted in some corrections which included adding zinc (10 mesh) to the solution at 1/4 teaspoon per gallon.

Oh yeah, the first batch of caramel colored stuff was dissolved with HCl then based back up to 14 and re-titrated after letting it zinc for a week... It yielded 1 gallon of pure white precipitate.

So here is the plan, place the solution into gallon plastic jugs (milk jugs). Fill them up about 3/4 full. Add 1/4 teaspoon of zinc shavings (10 mesh) into each jug, cap it and shake well. Lift the cap slightly then to allow for gas escape and place somewhere safe... Each day, shake the jug once or twice to mix up the solution (with the cap in place) and then uncap slightly and set back in place for the day... We do our burn and boil/filter on Saturday morning and let the solution zinc until the next Saturday when we filter out the zinc and then titrate. You only have to add the 1/4 teaspoon of zinc once, not everyday... the zinc will turn into a dark black powder which settles on the bottom of the jugs. The zinc pulls out the sulfur as zinc sulfate.

One ounce of gold should yield about 2 gallons of M1 and still return 80 percent of your metal. At least that's what we get.

So now you know... If there is ANY sulfur in the solution, you will not get M1...

BTW, the sulfur gets into the solution from the gold, The Asian gold we use (Canadian ML too) is precipitated gold, they use Sulfur Dioxide I think to precipitate it out from solution... So unless you dig up the gold from the earth or use pure natural nuggets, get some zinc (10 mesh).

Q. Is the burn time for the M-1 and M-3 about the same (15-20 min.) and is there any negative effect from adding a little time to the burn?

A. The burn times can be the same. We did 20 minutes for gold and 10-15 minutes for black sand.

Q. After the burn and cool down, do you think there is anything that could be added to the unreacted sodium, other than a little water mist (and run like hell) to neutralize it? (maybe a little black sand or something) Probably a dumb question!

A. Not a dumb question. Not that I know of, the sodium must be totally reacted during the burn in order for there not to be any left to react with the water spray... using an ounce of gold, we would need to cut down the sodium amount by quite a bit... There is plenty of black sand at 1 to 2 cups to totally use up the sodium atoms... Use water and be careful.

7-11-99 UPDATE

We use 2 ounces of sliced sodium covered by ½ cup of M3 black sand per burn. You can use a stainless steel burn pan twice only. After that it's too warped to be useful. After the ½ cup burn, you can shake off about ¼ cup of unreacted sand to be burned later. We no longer wet down the M3 after the burn, as we never got any sodium reaction and we wanted to avoid the NaOH splashing during the chisel-out. This works very well and then we just grind it in a mortar and pestle then put ½ cup into the 12 quart for the boil. After the boil, you can add more water and lye to the sludge and reboil. We add another ½ cup of burned M3 sand to the sludge in the pan. In this way, we get a second boil on the first boil while boiling the second burn the first time (huh?)

Cheers,

The Tampa Team:

Alison A..

Avi Z.

Don M.

Doris D

Jim R.

Joseph G.